Efficiency is paramount in today’s business world. Anyone who wants to be successful cannot ignore two essential tools: Enterprise Resource Planning (ERP) and Supply Chain Management (SCM).

But how exactly do ERP and SCM complement each other? What are the differences between an ERP system and SCM? And more importantly: What advantages does their integration bring?

Here we show you how these systems work together, what advantages arise from this symbiosis, and how companies can leverage them. We will cover the fundamentals of both systems, explain how they interact, and outline best practices for their implementation.

Fundamentals of Supply Chain Management (SCM)

Supply chain management is about not only overseeing the processes surrounding the production and delivery of products, but also optimizing them from start to finish. The goal is to reduce costs, streamline delivery times, and maximize customer satisfaction. Collaboration plays a key role here: suppliers, manufacturers, distributors, and customers must work hand in hand to ensure a smooth supply chain.

The essential building blocks of supply chain management are diverse and range from demand forecasting and procurement to production and storage, all the way to transport and final delivery to the customer.

Effective supply chain management therefore relies on transparency and control along the entire supply chain. The use of real-time data enables rapid responses to new information and allows for decisions to be made on a solid data foundation. However, the complexity of global markets presents companies with significant challenges that require a flexible and agile approach.

However, supply chain management should not be viewed in isolation; it is deeply intertwined with other areas of the company, particularly the enterprise resource planning (ERP) system. ERP systems provide the technological foundation necessary for capturing, analyzing, and utilizing the data relevant to SCM.

The role of ERP software in supply chain management

ERP systems form the core of modern business management. They integrate diverse business areas – from financial accounting and human resources to production – into a unified system. Think of ERP software as the central nervous system of a company, consolidating data and processes in a central database. This harmonization makes it significantly easier for companies to streamline their operations, increase efficiency, and make decisions based on solid data.

In the context of supply chain management, the role of the ERP system should not be underestimated. ERP functions help to oversee and control the supply chain from demand planning and procurement to delivery. This 360-degree view makes it possible to orchestrate the supply chain in such a way that it is not only efficient but also resilient to unexpected disruptions.

Ultimately, companies with ERP systems are also able to react quickly to market changes. They can adjust their warehouses to ensure they have neither too much nor too little stock and fine-tune their production plans to precisely match current demand. These systems also provide deep insights into the efficiency of the entire supply chain, from assessing supplier reliability to verifying transportation effectiveness. Such precise information is crucial for identifying problems early, improving processes, and ultimately ensuring greater customer satisfaction.

Integration of ERP and SCM

A key benefit of this close integration between ERP and SCM software is the ability to improve data accuracy and consistency. When information flows seamlessly and in real time within a single system, duplication and errors can be avoided. This greatly facilitates decision-making, as it allows for the use of current and comprehensive data from across the entire supply chain.

Furthermore, an integrated system significantly enhances a company’s planning capabilities. By accessing precise data from the ERP system, supply chain management can react more flexibly to changes in demand, manage inventory more effectively, and optimize production planning.

However, to successfully integrate ERP software and SCM, several best practices must be followed. Thorough planning and analysis of existing processes and systems are essential to identify integration points and understand the impact of the integration on existing workflows. It is also important to set clear integration goals and gain the support of both management and end users.

A phased implementation approach can be helpful in minimizing risks and allowing for continuous adjustments. Furthermore, it is crucial to provide adequate training for employees so they can effectively use the new processes and systems.

Challenges and solutions

Integrating ERP and SCM systems can significantly advance companies, but it also presents them with several challenges. These range from the technical complexity of the integration and employees’ natural reluctance towards innovation to concerns about data quality and security.

Complexity of integration

Connecting ERP and SCM systems can be tricky due to their different technical foundations and the specific processes they control. Careful planning in advance and the selection of suitable integration platforms that ensure seamless communication between the systems are essential. Working with IT service providers like SYNERPY, who already have experience with such integrations, can be crucial in avoiding potential pitfalls.

Resistance to change

It’s human nature to be skeptical of new ways of working. Open communication about the benefits of integration, along with comprehensive training, can help dispel concerns and foster employee acceptance. Furthermore, it’s crucial to actively solicit and consider user feedback to improve the usability and effectiveness of the new systems.

Data quality and security

Increased data exchange between systems raises questions regarding data integrity and security. It is recommended to establish clear data maintenance guidelines and conduct regular security audits. Modern data encryption technologies and protection mechanisms against unauthorized access should also be implemented.

Future trends in ERP and SCM

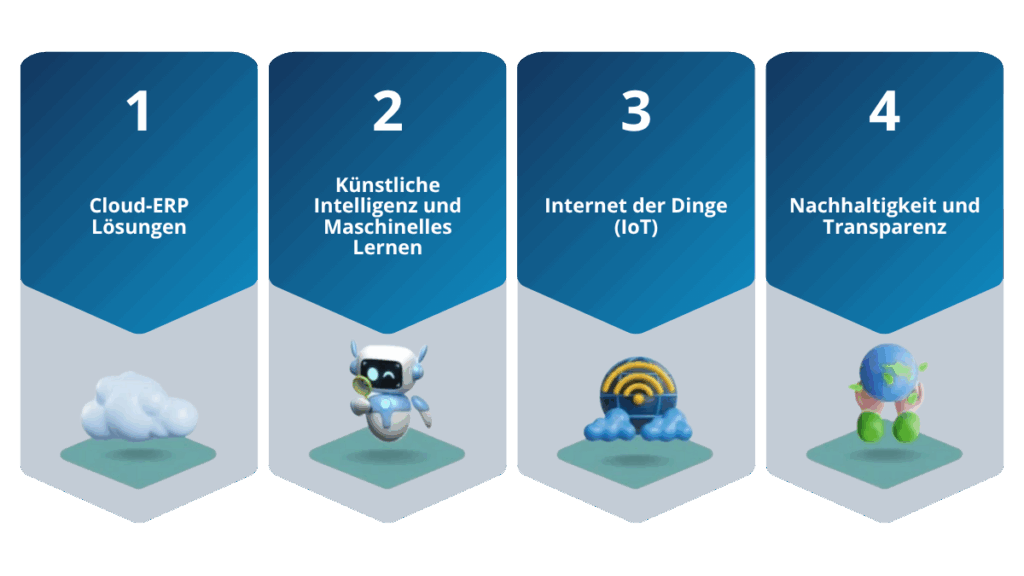

The world of technology is constantly evolving, and with it, the systems that companies use to manage their resources and supply chains. A look into the future of ERP and SCM reveals exciting trends that have the potential to further improve the efficiency and responsiveness of businesses.

Cloud ERP solutions

More and more companies are relying on the flexibility and scalability of cloud solutions for their ERP and SCM systems. This technology not only offers improved access and increased efficiency, but also facilitates rapid adaptation to changing market conditions. The ability to update or expand systems without significant lead time makes cloud ERP particularly attractive.

Artificial Intelligence and Machine Learning

AI and machine learning are transforming ERP and SCM systems. They enable the recognition of patterns in large datasets, the creation of forecasts, and the automation of decision-making processes. From precise demand planning to optimized warehouse management, new opportunities are emerging to increase efficiency and customer satisfaction.

Internet of Things (IoT)

By connecting devices and sensors, the IoT offers the possibility of collecting real-time data along the entire supply chain. This leads to better monitoring and control of processes and improves transparency from production to delivery to the end customer.

Sustainability and transparency

Conclusion

The seamless integration of ERP and SCM systems is essential for businesses today to increase efficiency, transparency, and customer centricity. ERP software, in particular, has become virtually indispensable for companies, as it enables the integration of many more solutions, such as Customer Relationship Management. While implementation challenges exist, the long-term benefits far outweigh them. Furthermore, the emergence of new technologies like cloud computing, AI, and a focus on sustainability opens up promising prospects for the future of these systems. Companies that proactively embrace these developments not only improve their operational performance but also contribute to a sustainable economy. Ultimately, the combination of ERP software and SCM is crucial for successfully meeting both current and future market demands.