How can companies strike the right balance between efficient inventory management and maximum customer satisfaction? We present material requirements planning (MRP). MRP is central to manufacturing companies striving for maximum efficiency while minimizing their inventory costs. Given the relentless competitive pressure in the market, skillful and flexible management of material flows is proving to be a critical success factor. This is where the Enterprise Resource Planning (ERP) system becomes crucial – it forms the foundation upon which the optimization strategies of MRP rest.

Here, we delve deeper into the challenges and solutions that material requirements planning (MRP) with ERP systems brings, including the various planning techniques and their integration into overall business processes. We also highlight the numerous advantages that ERP systems offer in this area and offer a glimpse into how advancing digitalization will further transform the landscape of material requirements planning (MRP).

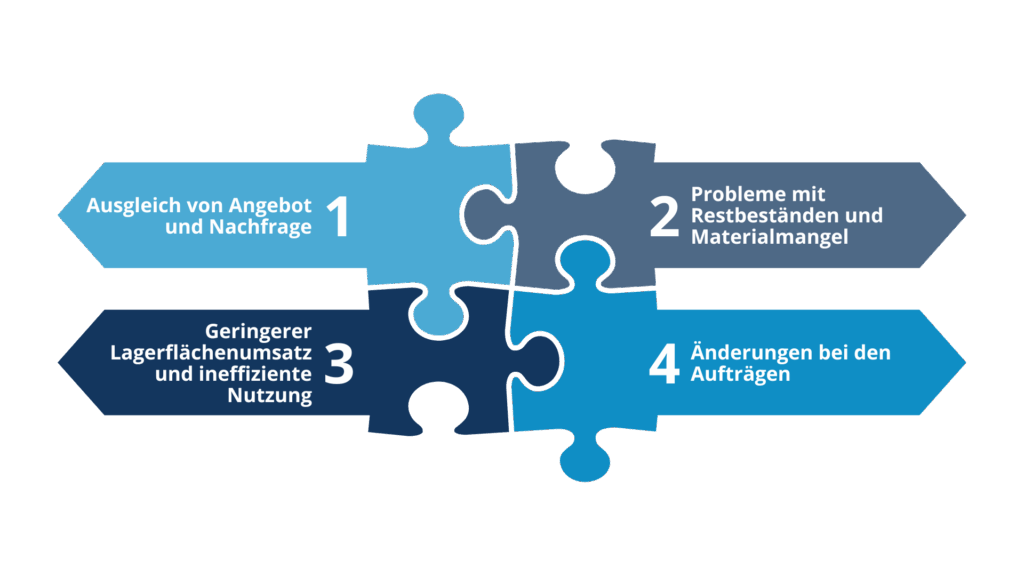

Challenges in Material Requirements Planning (MRP)

At the heart of material requirements planning (MRP) lies a demanding balancing act that requires a high degree of skill and foresight from companies to effectively achieve their production goals while keeping costs under control:

Balancing supply and demand

One of the main goals of material requirements planning (MRP) is to find a balance between the supply of materials and the demand for products. This can be difficult, as companies face unpredictable

Problems with remaining stock and material shortages

Excess inventory ties up capital and leads to higher storage costs, while a shortage of materials and components can result in production delays and dissatisfied customers. Finding the right balance requires precise planning and the ability to react quickly to changes. Ineffective material requirements planning (MRP) can therefore lead to financial losses.

Lower warehouse space turnover and inefficient utilization

Poor material requirements planning (MRP) can also lead to inefficient use of warehouse space. If the warehouse is overcrowded with certain materials, this can result in a lack of space for other necessary materials. This not only impairs warehouse efficiency but also causes additional costs due to the need for external storage facilities.

Changes to the orders

Order changes are not uncommon in the manufacturing industry. However, they require flexible adjustments to material requirements planning (MRP) to avoid delays and conflicts in production. The challenge lies in quickly adapting the production plan and material requirements to meet the changed demands.

ERP systems thus offer solutions to these challenges through the integration of real-time data and the automation of planning processes. These systems enable dynamic adaptation of material requirements planning (MRP) to changing production conditions and help to effectively manage the aforementioned problems.

Fundamentals of materials management and its objectives

Materials management plays a central role in optimizing production processes and ensuring material availability. It encompasses the planning, control, and monitoring of material flows from procurement to delivery of the finished product. The goal is to guarantee an efficient material supply that enables products to be manufactured on time and to the required quality.

Tasks and objectives of materials management

The primary task in materials management is to guarantee the seamless availability of resources in adequate quantity and quality at the required time and place. This responsibility includes analyzing the need for materials and components, identifying and selecting suitable suppliers, the material ordering process, storage, and internal logistics. Materials management thus leads us to the two categories into which its desired results can be divided: formal and material objectives.

The formal objectives focus on minimizing capital tied up in inventory, reducing inventory holding costs, and mitigating risk through inventory optimization.

The material objectives, on the other hand, focus on ensuring optimal availability of the materials.

The guiding principle here is that all necessary materials and components must be available in the required quality and quantity to enable a smooth production process and the fulfillment of customer requirements.

By integrating materials management into ERP systems, companies can achieve these goals more effectively. ERP systems provide the necessary tools and data to optimize materials management and ensure seamless coordination between different business units.

Material Requirements Planning (MRP) methods

Deep within ERP (Enterprise Resource Planning) systems, various strategies are employed to accurately and effectively calculate material requirements. These strategies can be broadly categorized into two main approaches: program-oriented demand forecasting and consumption-oriented demand forecasting.

Program-oriented needs assessment

This approach is based on the company’s production or sales program. It aims to determine future material requirements based on planned products or orders. Bills of materials, work plans, and parts usage records are used to translate the primary demand for finished products into a secondary demand for raw materials, individual parts, and assemblies. Comparing the calculated gross demand with existing inventory levels yields the net demand that actually needs to be procured. This method is particularly suitable for companies with customer-specific, one-off, or small-batch production, where demand can be derived directly from orders.

Consumption-oriented demand assessment

In contrast, consumption-based demand forecasting relies on historical consumption data and statistical methods to predict future material requirements. This method is frequently used for standard materials or C-parts whose consumption patterns are relatively stable. By analyzing past consumption data and considering trends and seasonal fluctuations, a relatively accurate forecast of material requirements can be generated for any product. This method is particularly suitable for planning materials with regular consumption and low unit value.

Level of automation and adaptability

ERP systems allow for the automation of these demand forecasting processes and offer the necessary flexibility to tailor them to the specific needs of the company. By integrating real-time data from production, sales, and warehousing, ERP systems can continuously adapt material requirements planning (MRP) to changing market or production conditions. This helps minimize overproduction and excess inventory, avoid supply bottlenecks, and ultimately maximize production efficiency.

Integration of Material Requirements Planning (MRP)

The successful integration of material requirements planning (MRP) into enterprise resource planning (ERP) systems forms the backbone of an efficient and responsive production chain. This integration enables companies to connect various business areas such as sales, production, purchasing, and warehousing on a unified platform.

The role of disposition and its optimal setting

Within an ERP system, inventory planning is a critical area that directly impacts material availability and storage costs. Effective planning ensures that the necessary materials are available at the right time, in the required quality and quantity. It helps to keep inventory levels lean and minimize the risk of production delays. ERP systems allow for detailed adjustments to inventory parameters such as minimum stock levels, safety reserves, and lead times to achieve an ideal balance between warehousing costs and delivery readiness.

Relationship between materials management and production planning

The seamless integration of material requirements planning (MRP) with production planning is crucial for a company’s success. ERP systems establish a direct link between the production plan and material requirements by linking

Advantages of Material Requirements Planning (MRP)

Overall, implementing material requirements planning (MRP) within an ERP system brings a multitude of advantages that directly impact efficiency, cost reduction, and customer satisfaction:

Optimized inventory levels

Through precise planning and control of material inventories, companies can reduce excess stocks while ensuring that sufficient materials are available for production.

Improved production planning

Integrated Material Requirements Planning (MRP) enables close coordination between production and procurement processes.

Increased flexibility and responsiveness

ERP systems offer real-time data that enables companies to react quickly to changes in demand or the supply chain.

Reduction of planning and forecasting errors

By using historical data and advanced analysis tools, ERP systems can make more accurate predictions about material requirements.

Digitalization and the future of material requirements planning (MRP)

The ever-increasing digitalization also has a profound impact on material requirements planning (MRP), opening up new opportunities for optimizing production and supply chain processes. Modern ERP systems integrate advanced technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) to refine forecasts, enhance automation, and provide real-time insights into the supply chain. In the future, the capabilities of these technologies will offer companies a decisive competitive advantage. The continuous evolution of ERP systems promises even closer integration of all business areas, making material requirements planning (MRP) even more efficient, precise, and responsive.

Conclusion

Ultimately, material requirements planning (MRP) with ERP is a crucial lever for companies to remain competitive today. By continuously adapting and improving their ERP systems, companies can ensure that they not only meet current demands but also proactively address future challenges.