In today’s technology-driven world, data has become a valuable asset, especially when it comes to the successful execution of projects and product development processes.

However, organizing and managing the large amounts of data that arise during a project is a complex challenge for companies of all sizes.

Whether you are an established company looking to optimize its data management or an up-and-coming start-up seeking effective solutions for product development, PDM systems will help your project teams seamlessly share information, manage versions, implement changes efficiently, and thus boost your company’s innovative power.

Let’s work together to find out how this intelligent technology can create sustainable added value for your business and how to choose the right PDM solution that best meets your specific requirements.

How do PDM systems work?

PDM systems serve as central databases for the structured capture, management, and sharing of product information. They offer versioning capabilities for change tracking, access control for security, data linking for better understanding, and promote team collaboration.

Through seamless integration with other applications, they support efficient project management and contribute to increasing the innovative strength of companies.

The advantages of a PDM system

Implementing a PDM system offers companies a multitude of benefits that positively impact their product development and overall business. Here are some of the most important advantages:

Improved data organization and management

PDM systems create a structured database in which all product data is centrally stored and categorized. This makes it easier to find information, avoids redundant data, and reduces the risk of outdated or incorrect data.

Efficient change tracking

The versioning function of a PDM system makes it possible to precisely document and track changes to product data. This increases transparency regarding changes, avoids errors, and improves team collaboration.

Improved data security and access control

PDM systems offer comprehensive access rights and security features to control access to sensitive data and prevent unauthorized manipulation. This ensures that information is only accessible to authorized employees and that confidentiality is maintained.

Improved teamwork

Thanks to the ability to simultaneously work on project data and leave comments, PDM systems promote collaboration and information exchange within the team. This can reduce communication bottlenecks and accelerate product development.

Faster time-to-market

Optimized data management and efficient teamwork enable faster product development and launch. This gives companies a competitive advantage and allows them to respond more quickly to changing customer needs.

Reduced costs and errors

A well-implemented PDM system leads to better control over production and development processes, which in turn results in fewer errors and less scrap. Avoiding duplication of effort and using up-to-date data also reduces costs.

Seamless integration with other systems

Modern PDM systems can be seamlessly integrated into other business applications, such as CAD software or ERP systems. This enables seamless data exchange and increases efficiency across the entire value chain.

PDM vs. PLM: The differences

Product Data Management (PDM) focuses primarily on the management and organization of product data. It is designed to capture, version, and control data such as CAD models, drawings, bills of materials, and technical documentation.

The main goal is to ensure the smooth flow of information within the development process and to guarantee data consistency.

In contrast, Product Lifecycle Management (PLM) considers the entire life cycle of a product, from conception through development and manufacturing to maintenance and disposal.

In addition to data management, it also encompasses aspects such as process management, project management, quality control, and team collaboration. PLM takes a holistic view of the product development process and offers a broader range of functions that go beyond pure data management.

Overall, it can be said that PDM and PLM are closely related, but have different focuses.

While PDM focuses on the efficient management of product data, PLM considers the entire life cycle of a product and offers a more comprehensive solution for product management in all phases of its development and use.

Ultimately, PDM can be described as an integral part of PLM, which creates the foundation for a successful PLM.

ERP and PDM – Is integration worthwhile?

Enterprise Resource Planning (ERP) and Product Data Management (PDM) are two powerful software solutions that support different areas within companies.

While ERP systems cover resource planning, finance and logistics, PDM systems focus on managing product data and supporting product development.

Whether integrating both systems makes sense depends on individual requirements and the complexity of the business processes. Here are some aspects to consider:

A holistic view of the company

The integration of ERP and PDM can help companies gain a holistic view of their business processes.

When both systems are linked, information can flow seamlessly between departments, leading to improved transparency and better information exchange.

For example, changes to bills of materials or material data in the PDM system can be automatically transferred to the ERP system to optimize production planning and material procurement.

Avoiding redundancies and errors

Integrating ERP and PDM helps to avoid redundancies and inconsistencies in the data.

Efficient change management

Change management is of great importance in both ERP and PDM systems.

Integration allows changes to product data to be seamlessly tracked and approved across systems. This ensures a structured and traceable process, which can prove extremely useful, especially in complex product development environments.

Challenges in integration

However, integrating ERP and PDM can also present technical and organizational challenges. Both systems may have different data models, processes, and interfaces, which can complicate seamless integration.

It is important to thoroughly analyze the systems and, if necessary, to use standardized ERP interfaces or middleware solutions to ensure successful integration.

In many companies, the integration of ERP and PDM can be beneficial, as it can lead to improved data consistency, more efficient information exchange, and a holistic view of the company.

Particularly in manufacturing companies with complex product structures and processes, linking both systems can offer significant advantages. However, the integration should be carefully planned and tailored to the individual needs and circumstances of the company to ensure smooth and successful implementation.

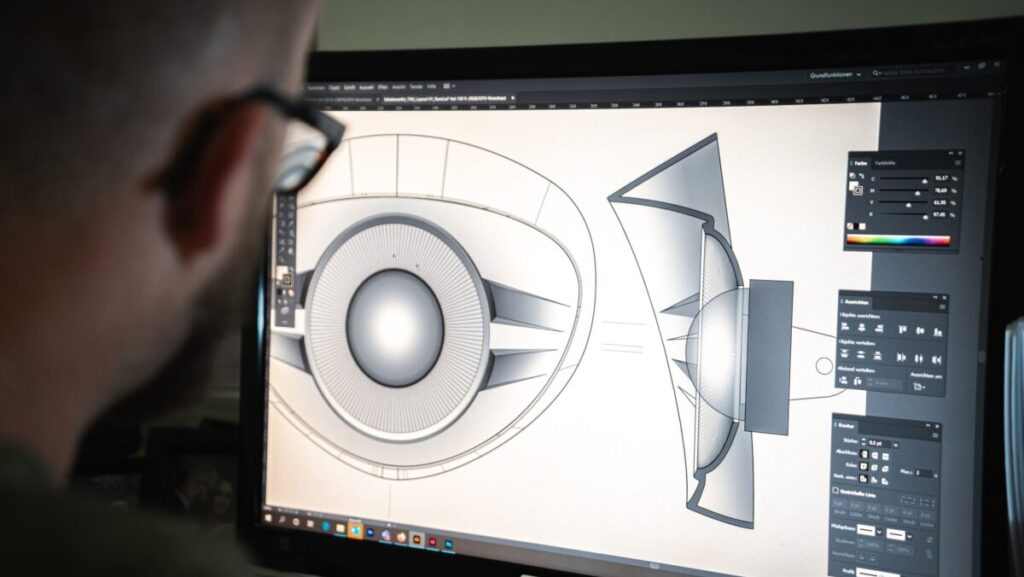

PDM and CAD

PDM systems and CAD (Computer-Aided Design) software form a highly effective partnership for product development. While CAD programs enable the creation of detailed 3D models and drawings, PDM comes into play to efficiently manage, organize, and control this design data.

The seamless integration of PDM and CAD allows designers and engineers to collaborate effectively while working on a central dataset.

PDM ensures that all CAD models, drawings, and related information are stored in a structured and versioned data repository. This guarantees that all team members always have access to the most up-to-date and relevant data.

Furthermore, the combination of PDM and CAD enables efficient management of changes and tracking of the entire development process.

All modifications to the CAD data are documented, approved, and easily traceable. This contributes to increased productivity, better error prevention, and faster time to market.

Overall, the integration of PDM and CAD offers a synergy effect that optimizes product development and helps companies bring high-quality products to market faster and more efficiently.

Conclusion

PDM systems have proven to be indispensable tools for companies seeking efficient product development and optimized data management.

In a time of ever-increasing competition and rapidly changing market demands, PDM systems play a central role in meeting the challenges of modern business life.

Regardless of a company’s size or industry, PDM systems can help optimize product development, reduce costs, minimize errors, and ultimately strengthen competitiveness.

When choosing a PDM system, it is crucial to consider the individual requirements and processes of the company in order to find the best possible solution.

Overall, PDM systems represent a smart investment that helps companies accelerate their product development, use their resources more efficiently, and increase their innovation capacity.

By providing a solid framework for data management and collaboration, the PDM system paves the way for a successful future in a dynamic and competitive business environment.