Resource management

Here, costs can be saved and productivity increased. ERP software in mechanical engineering helps to increase machine capacity and material inventories. Furthermore, it enables effective personnel management and conserves employee resources. Precise data analysis allows for the early identification of bottlenecks within the company, successful optimization of inventory levels, and maximization of machine utilization. This leads to long-term improvements in the efficiency of your equipment and your employees.

Integrate business processes

ERP software allows you to improve the integration of various business processes. This enables you to link all processes, from order placement and material procurement to delivery. This automatically leads to improved communication and thus better collaboration between departments. Furthermore, information about the entire production cycle is stored and made available in real time.

Improving quality management

Quality is of paramount importance for the products of the mechanical and plant engineering sector. Only through innovation and quality can companies today differentiate themselves from the competition, especially from Asia. Modern ERP solutions enable precise adherence to quality standards in this industry. This includes, above all, the seamless traceability of the machines, materials, and processes used. Furthermore, quality controls can be integrated into ongoing operations. Companies thus benefit from the early detection of errors and can intervene in the production process in a timely manner to prevent scrap. This saves costs and increases flexibility.

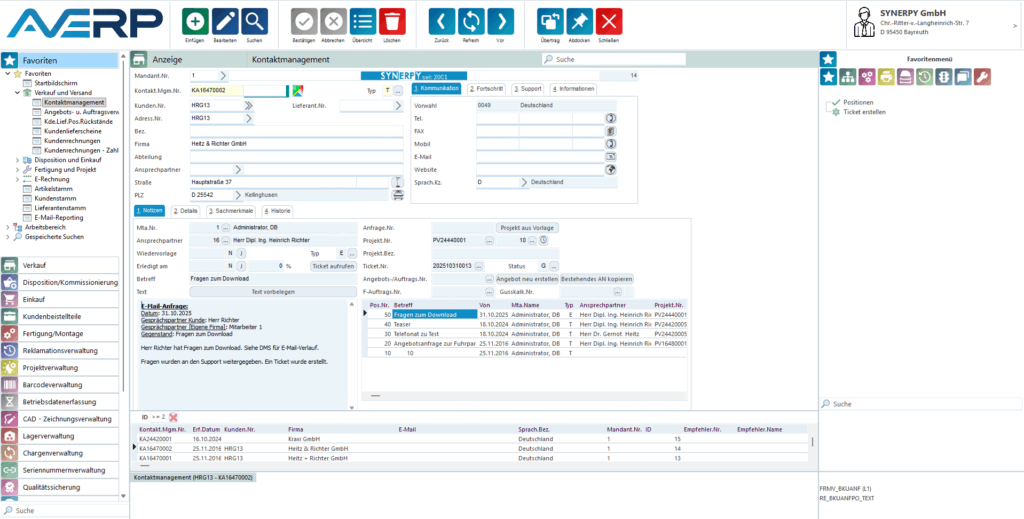

Customer Relationship Management (CRM)

ERP software is also successfully used in customer relationship management. Integrated CRM functions enable a holistic view of customer requirements. Customer needs vary from customer to customer and are often diverse, complex, and require individual measures and solutions. Whether orders or service requests: an ERP system always ensures the right overview. Even customer-specific adjustments can be easily accommodated. This not only optimizes the supply chain but also strengthens customer loyalty.

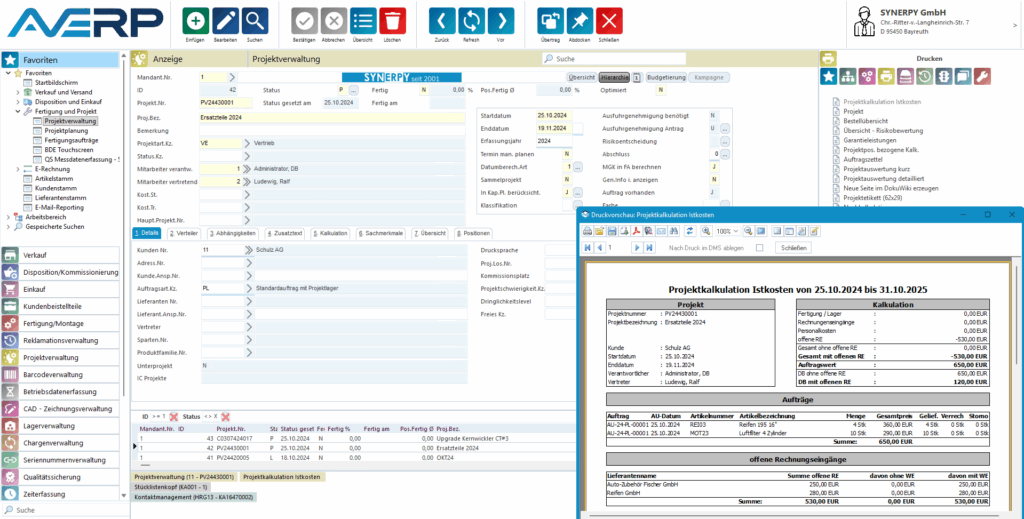

Project management and order processing

ERP systems for discrete manufacturing enable detailed planning and monitoring of projects. Each order is treated as an independent project, allowing for precise resource planning and deadline control. This is crucial for managing the complexity of discrete manufacturing, where each product has unique requirements and specifications.

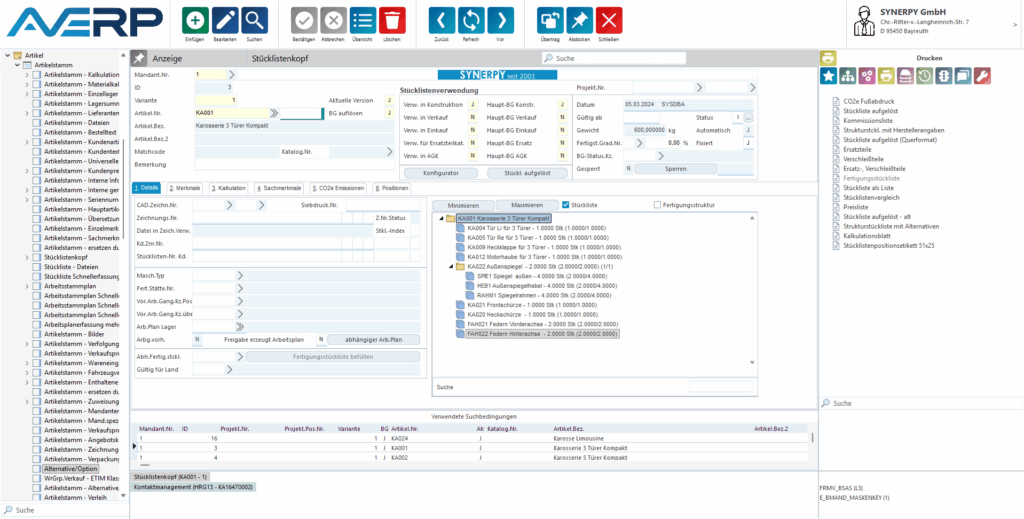

Bill of materials and variant management

Bills of materials and product variants are ubiquitous in mechanical and plant engineering. ERP software for discrete manufacturing enables the efficient management of bills of materials, including all required components and materials. At the same time, it supports the management of product variants, thus facilitating adaptation to individual customer requirements.

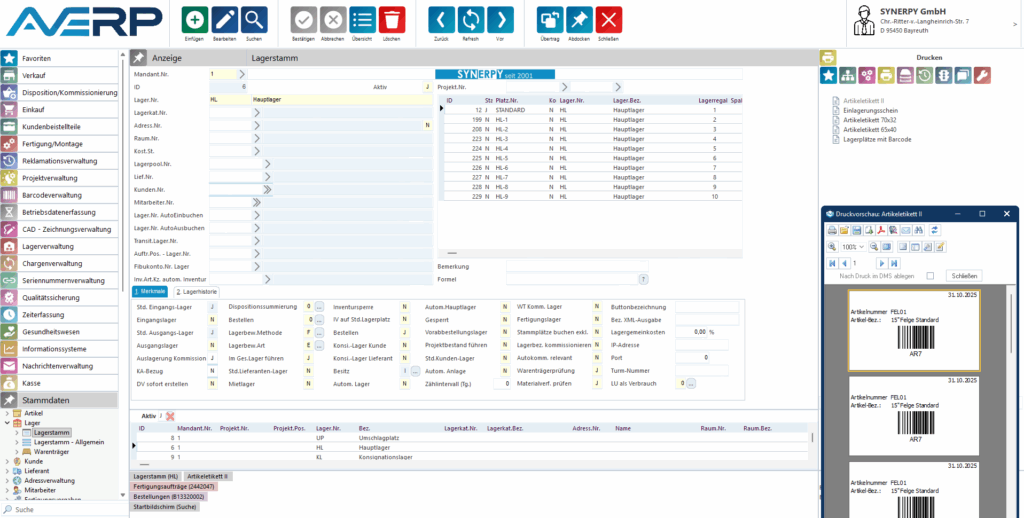

Material and warehouse management

Precise material management is crucial in make-to-order manufacturing. ERP systems integrate material flow and warehouse management, giving companies a clear overview of their inventory levels. This reduces the risk of material shortages and supports cost-effective procurement.