Discrete manufacturing plays a central role in the world of manufacturing. It encompasses the production of products that can be identified as countable units – from automobiles to complex machines.

ERP systems offer an integrated solution for managing all business processes – from production and logistics to finance. In discrete manufacturing, they enable precise control of production processes, improve material and capacity planning, and facilitate adaptation to changing market demands. By providing a comprehensive view of all business processes, ERP systems help increase efficiency, reduce costs, and strengthen competitiveness.

We examine how ERP systems meet the specific requirements of discrete manufacturing and how companies can select and effectively implement the right system. We look at the core functions of an ERP system that make it indispensable for discrete manufacturing companies and discuss how these systems contribute to optimizing production processes and increasing overall performance.

Fundamentals of discrete manufacturing

Discrete manufacturing refers to a production environment in which products are manufactured as countable units. These products are created from a variety of materials and components, with each product possessing its own unique properties. Typical examples of discrete manufacturing can be found in industries such as mechanical and plant engineering, mass production, vehicle manufacturing, and the automotive industry.

A characteristic feature of discrete manufacturing is the variety of manufacturing methods. These include:

Single-unit production

Here, each product is individually designed and manufactured, often over a long period of time. Examples include ships or specialized machinery.

Series production

This involves the production of large quantities of identical products. These manufacturers are often part of a larger supply chain and must precisely coordinate their processes to operate economically. Typical products include consumer goods such as umbrellas or cars.

Variant production

This type of manufacturing produces products with the aim of standardization and modularization, in order to allow for a certain degree of individualization. Examples include kitchens or furnishings.

The challenges in discrete manufacturing are diverse and complex. They range from the precise planning and control of production processes to managing bottlenecks and waste. An ERP system offers a solution for efficiently overcoming these challenges and optimizing the production process.

What is an ERP system?

This is achieved by digitally mapping all of a company’s business processes and consolidating them in a shared database. This makes it possible to streamline, integrate, or even automate many processes. An ERP system consists of various modules, each covering specific areas of the business.

The central role of an ERP system in discrete manufacturing stems from its ability to simplify and coordinate complex processes. By integrating various

The role of ERP in discrete manufacturing

In discrete manufacturing, the adaptability of ERP systems is crucial. Since there is no single, unified concept of “discrete manufacturing,” ERP systems must be flexible enough to meet the diverse requirements of different production processes.

The goal of a professional ERP system is to comprehensively map all business-critical processes. This includes not only the actual manufacturing processes, but also all upstream and downstream process steps, such as product development, material procurement, and cost accounting.

The flexibility of an ERP system allows for the standardization of processes where appropriate, as well as the consideration of specific requirements from individual business units. This creates a customized system that optimizes the company’s value creation while simultaneously minimizing implementation costs.

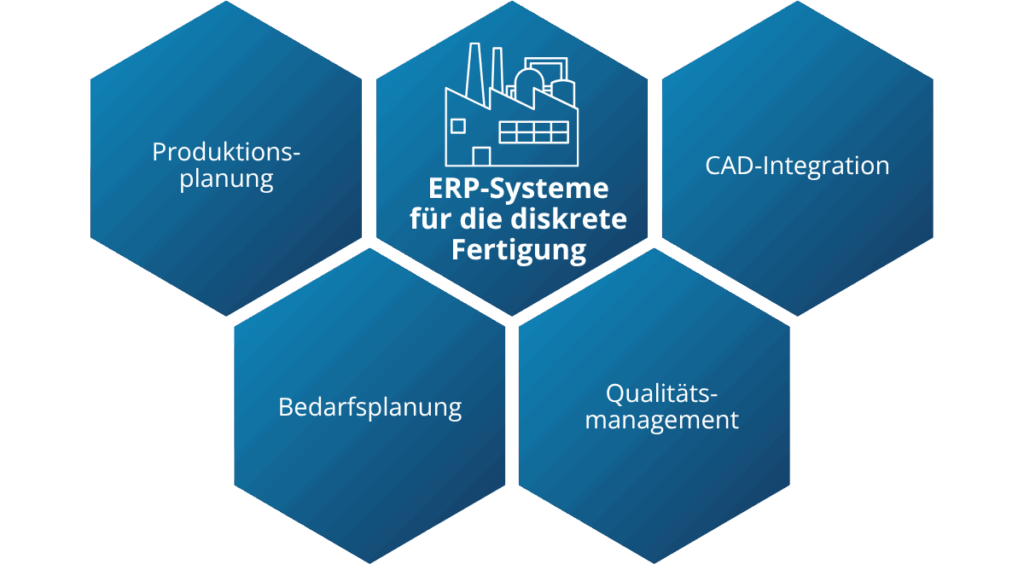

Core functions of ERP systems in discrete manufacturing

ERP systems offer a range of key functions specifically tailored to the needs of discrete manufacturing:

Production Planning

Efficient production process design is crucial. ERP systems enable centralized planning, control, and monitoring of all necessary resources for the production process. They take into account factors such as personnel, processing capacity, and maximum production capacity. This leads to improved planning, avoidance of bottlenecks, and optimal utilization of human resources.

CAD integration (Computer Aided Design)

Many ERP systems offer integration or an interface to CAD programs. This connection simplifies the development and production process, as bills of materials can be updated automatically and developers have direct access to relevant information.

Demand planning

ERP systems help companies predict future customer demand based on historical data. This enables more accurate sales forecasting and efficient planning of material and production resources.

Quality management

A crucial aspect of discrete manufacturing is maintaining consistent product quality. ERP systems enable the management and monitoring of quality from goods receipt through to the production process. Deviations are quickly identified and can be rectified immediately.

Selecting a suitable ERP system

When selecting an ERP system for discrete manufacturing, companies must consider several key factors:

Industry-specific requirements

Different types of discrete manufacturing require different ERP functionalities. The choice of an ERP system should be tailored to the specific needs of the company and its production processes.

Bill of Materials Management (BOM Management)

Efficient management of bills of materials (BOMs) is crucial for production planning. The selected ERP system should be able to effectively manage and update BOMs.

Preliminary and subsequent calculations

ERP systems should support companies in estimating production costs and help assess the profitability of individual products.

Integration with other systems

The ability to seamlessly integrate with other systems, such as CAD software, is essential for optimizing the production process.

Demand planning

A good ERP system enables accurate demand planning based on historical sales data and helps to anticipate future trends and requirements.

Bill of materials management with ERP

Bills of materials (BOMs) are a central element in discrete manufacturing. They serve not only as purchasing lists but also as a guiding thread throughout the entire production process. In an ERP system, all relevant production data is recorded in these lists, including raw materials, components, manufactured parts, and information on processing and outsourcing.

Bills of materials (BOMs) simplify production planning and control by providing a clear overview of all components required to manufacture a product. Their integration with the ERP system ensures that BOMs are always up-to-date and can be quickly adapted as needed. This enables efficient material procurement and management and contributes to optimizing the entire production chain.

Economic analysis: Preliminary and subsequent calculations

A key aspect of using ERP systems in discrete manufacturing is the ability to perform pre– and post-calculations. These calculations enable companies to estimate the costs and timeframe for producing an item and to assess its profitability.

Preliminary calculations serve as preliminary cost estimates and aid in budget planning and pricing. Post-calculations, on the other hand, are performed after the production process is complete to determine the actual costs and compare them with the estimates. This information is crucial for a company’s financial planning and long-term profitability analysis.

Conclusion

As a provider of customized ERP systems, we understand the unique challenges of discrete manufacturing. Our ERP solutions are designed to reduce the complexity of production processes, create transparency, and increase efficiency.

With our expertise in developing flexible and adaptable systems, we support companies in optimizing their processes and strengthening their competitiveness. We firmly believe that the right ERP solution is not just a tool, but a strategic partner for success in today’s dynamic manufacturing landscape.